Table of contents

In 2021, there were 169 fatalities in the workplace, within the Transport, Postal and Warehousing industry. This is the highest number of fatalities, according to Safe Work Australia and accounts for 30% of all fatalities reported. There were also 130,195 serious injury claims made due to work-related injuries or illnesses. The transport, postal, and warehousing industry has a fatality rate of 7.9 per 100,000 workers. This is much higher than the overall rate of 1.3 per 100,000 workers across all industries.

The importance of prioritising safety in warehouses to prevent accidents and injuries

The most common causes of fatalities were vehicle incidents and being hit by moving objects. This highlights the importance of prioritising Work Health and Safety (WHS) in the transport, postal, and warehousing industry. Employers in this sector should take proactive measures to identify and address workplace hazards. As well as to ensure appropriate training and equipment are provided to workers, and encourage a strong safety culture. Taking these steps can help reduce workplace injuries and fatalities and create a safer working environment for all employees.

With so many people working in warehouses, it is critical to prioritise safety to prevent serious accidents and injuries. One of the most significant hazards in a warehouse is damaged racking. Damaged racking can cause items to fall, resulting in bodily injury and product damage. Therefore, investing in a solution that prevents damage to racking and reduces the risk of accidents is essential.

That’s where Colby’s rack protection systems come in, designed to protect the pallet racking from forklift impact. This helps reduce the risk of product damage and ultimately increases worker safety.

This article’ll discuss how Colby’s rack protection systems can improve warehouse safety and reduce costs.

Types of Warehouse Accidents

Warehouses are prone to various accidents, and some of the most common ones include forklift collisions, falling objects, and slips/trips/falls. These types of accidents can cause severe injuries to workers and significant damage to products and property.

Forklift Collisions

Forklifts are the most common vehicles used in warehouses, and if they collide with racks, severe damage can occur. Damaged racking can cause items to fall. This is not only hazardous for workers but can also lead to the loss of products. Furthermore, repairing damaged racks can be expensive, and in some cases, it might even require replacing the entire racking system.

Colby’s rack protection systems are designed to protect pallet racking from forklift collisions. This reduces the risk of damage to the racks and the stored products. Rack protection absorbs the impact of a collision. This prevents the forklift from causing severe damage to the racking and reduces the need for expensive repairs or replacements.

Falling Objects

Workers can accidentally drop objects, causing them to fall from heights and resulting in severe injuries. Even a small item falling from a high level can harm someone working below. Additionally, falling objects can cause damage to other products and equipment in the warehouse.

Colby’s rack protection systems feature components such as post protectors, beam protectors, and end protectors. All these components serve as an additional support layer for the products stored on the racks. They prevent products from falling off the racks by acting as a barrier. If an object does fall, the protection system helps prevent it from causing significant damage to other products or equipment.

Slips/Trips/Falls

A slippery surface, cluttered walkways, or uneven flooring can often cause warehouse slips, trips, and falls. These accidents can lead to fractures, sprains, and other injuries. If workers carry heavy objects when they slip, the consequences could be even more severe.

Colby’s racking systems can also help prevent slips, trips, and falls by storing the products securely on the racks. Having somewhere to store products reduces clutter on the warehouse floor. A safe and organised warehouse reduces workers’ risk of accidents and injuries.

Benefits of Colby’s Rack Protection

Colby’s Protect-a-Rack products are a valuable investment for businesses that want to:

- protect their assets,

- reduce costs, and

- improve warehouse safety and productivity in their warehouse operations.

The following benefits are essential for any business to maintain high standards of safety and efficiency:

Avoiding Damage to Racking

Rack protection absorbs the impact of collisions and prevents damage to the pallet racking. It also reduces the risk of products falling from the racks. Preventing damage caused by forklifts and other vehicles used in the warehouse will reduce the need for costly repairs or replacements.

Reducing Maintenance Costs

With Colby’s rack protection systems in place, the racking is less likely to sustain damage, which reduces the need for maintenance and repair work. This can result in lower maintenance costs over time, freeing up resources that can be used elsewhere in the business.

Improving Warehouse Safety

By preventing damage to the racking, Colby’s rack protection systems also reduce the risks of accidents caused by damaged or weakened racking. Additionally, the systems themselves can absorb impacts and prevent objects from falling, providing workers an additional layer of safety. By improving warehouse safety, businesses can minimise the risks of accidents and injuries and create a safer working environment for their employees.

Increased Productivity and Profitability

Improving warehouse safety using Colby’s rack protection systems can increase productivity and profitability. A safer working environment can minimise downtime caused by accidents and injuries. Workers can focus on their tasks and complete them efficiently. Additionally, businesses can save money by avoiding damage to the racking and reducing maintenance costs. This can then be reinvested in other business areas, ultimately boosting profitability.

Different types of Colby’s rack protection systems

Colby’s Protect-a-Rack system has different components to cater to various warehouse needs. The three most popular types are post protectors, beam protectors, and end protectors.

Upright Protectors

Colby racking upright protectors are designed to prevent damage to upright posts and the columns in a racking system caused by forklift collisions. They act as a barrier between the forklift and the post, absorbing impact energy and reducing the risk of damage or collapse to the racking system. These protectors can be customised to fit specific post shapes and sizes and are available in standard and heavy-duty options. Investing in Colby’s Protect-a-Rack Upright protectors helps to create a safer working environment, protect assets, and reduce maintenance costs over time.

Colby UU Beams

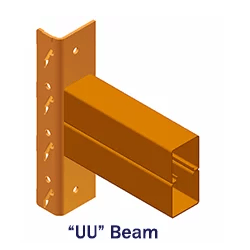

Colby’s Heavy Duty Front Impact Beam is a patented concept designed to reduce damage caused by frontal impacts from accidental collisions. The beam features a rib in the centre, which helps to absorb the impact of collisions and prevent damage to the beam and any products stored on it. While it may not be the most aesthetically pleasing beam on the market, it is highly effective in reducing damage and increasing the lifespan of your racking system.

Low Beam Protectors

Colby low beam protectors are designed to fit most rack uprights and protect against when the first beam level is very low.

Rack End protectors

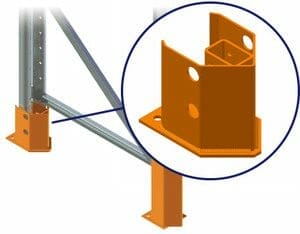

Pallet racking end guard protectors, also known as frame protectors, are designed to protect the most vulnerable part of a racking system from being damaged by forklifts or other vehicles. Colby’s Protect-a-Rack End Guards are installed a the end of storage aisles and protect the uprights, frames, and baseplates. These protectors wrap around the frame and are specifically designed to absorb the impact and deflect it away from these supporting elements of the structure. Available in standard and heavy-duty options, these protectors can be customised to fit specific frame sizes and shapes. Investing in Colby’s Protect-a-Rack End Guards helps to create a safer working environment for employees, protects assets extends the life of the racking system, and saves you money on maintenance costs over time.

Colby Beam Safety Clips – Cobra clips

Colby safety clips are a must-have if you’re looking to maintain the safety and stability of your pallet racking system. These safety clips are designed to securely lock the beams into the racking structure, ensuring they stay in place even during impacts or movement. While standard-duty safety clips are suitable for most installations, Cobra heavy-duty beam safety clips are recommended in areas that experience frequent impacts, especially when Colby protection is applied via “UU” beams.

Corner Protectors

A racking corner guard protector is designed to provide extra protection for the corners of racking installations, which are particularly vulnerable to damage from material handling equipment. A racking corner guard protector is a manufactured heavy steel plate specifically engineered to withstand impacts and reduce the risk of damage or collapse to the racking system. One of the main benefits of Colby’s corner protectors is that they are easy to install and can be anchored directly onto the corners of the racking system. This helps to ensure a secure fit and provides added stability to the structure.

Existing Damage or Racking Weakness

Total Racking Systems treats safety as a top priority. Ask us about our regular pallet rack safety inspections to check the structural integrity of your racking system. We can repair damage, make recommendations, and return your system to safe operating standards. Pallet racking systems must comply with AS4084-2012 standards and be inspected yearly. Regular inspections are important to maintain the safety of your pallet racking system, avoid potential hazards, and protect your personnel.

How to install Colby’s rack protection systems

Colby’s rack protection systems are designed to be easy to install. Here is a general guide on how to install Colby’s rack protection systems:

Step 1:

Before installation, ensure that the area around the racking system is clear of any obstacles or equipment that could interfere with the installation process.

Step 2:

If applicable, remove any existing protective covers and clean the surface where the new protectors will be installed.

Step 3:

For post protectors, slide the protector over the upright post and align it with the holes in the baseplate. Secure the protector to the baseplate using bolts or clamps.

Step 4:

For beam protectors, wrap the protector around the beam and secure it using bolts or clamps.

Step 5:

For end protectors, wrap the protector around the frame and ensure it is aligned properly before securing it with bolts or clamps.

Step 6:

For corner protectors, anchor the protector onto the corners of the racking system using bolts or clamps.

Step 7:

Once all protectors are installed, inspect the entire system to ensure that everything is securely in place and there are no loose or damaged components. It is important to note that the specific installation requirements may vary depending on the type of rack protection system you choose and the layout of your warehouse.

Investing in Colby’s rack protection systems is highly recommended to ensure that your warehouse is a safe and efficient workplace. You can find a solution tailored to your specific requirements with various options available to suit different needs and budgets.

Designed to fit just about every type of rack upright, the Colby Protect-a-RACK outperforms traditional steel and plastic rack protection systems through its unique, innovative design and ease of installation.

Don’t wait until an accident happens – take action today to protect your assets and your people with Colby’s rack protection systems. Contact us today to protect your business and your people with Colby Protect-a-RACK.

Next Steps:

- Get a Racking Protection Quote

- See more details about Racking Safety

- Contact Total Racking Systems for assistance

- Place an order for rack protection